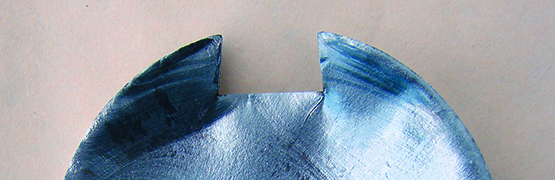

Identification of fracture mechanisms and causes of failure in parts and mechanical components.

Tensile, compression, bending and hardness tests.

Measurement of PM10, total, HCl, comp. organic, both gaseous emissions and air quality.

Conducting audits, visual inspections, tests and measurements to determine the structural integrity of the tanks, as well as carrying out global projects for the environmental evaluation of the sites.

Chemical analysis of metallic materials (ferrous and non-ferrous), non-metallic, minerals, sand, cement, waste.

Optical and electronic microscopy, characterization of metallographic structures, metallographic replicas, determination of inclusion content of steel, microhardness measurement, EDS analysis, particulate characterization.

Commissioning, annual periodic controls, and extension of useful life.

There are currently two certification systems according to Guide ISO / IEC 28 (IRAM 354) for products under Resolution 404/1999, Certification by Conformity Mark and Lot Certification (the latter regime incorporated by Resolution SCDDC 148 /1999).

Eng. Héctor Sbuttoni

sbuttoni@siderurgia.org.ar

☏ + 54 336 4462989 / 4460257 / 4461795 ext. 16